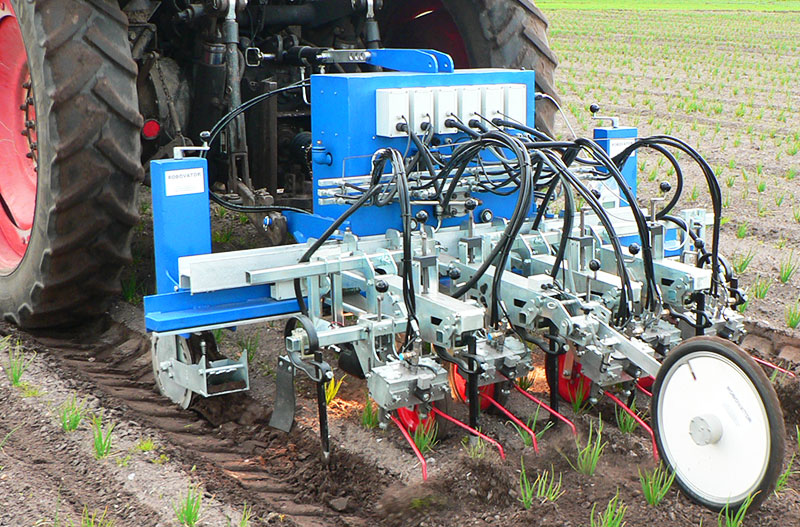

The Robovator is equipped with a special plant detection camera above each row, fitted on each parallelogram continuously monitors the passing plants

The Robovater is equipped with a special plant detection camera above each row.

It has a mechanical tool which is operated by hydraulic power. The “intelligent” weeding tools are normally staying in the row but are moved out of the row when a crop plant is passing. The hydraulic components are very robust and designed for operating at high speed and long life.

The specially designed plant detection cameras fitted on each parallelogram continuously monitors the passing plants. If a crop plant passes, the computer will send a signal to the hydraulic controlled tool which at the specified time will be moved out of the row. When the crop plant has passed, the tool will be moved into the row again. If there is a gap in the row e.g. one or more plants are missing, the tool will just stay in the row. The automatic lateral control will make sure that the machine stays in the exact position even if the tractor goes off track.

- Automatic hoeing in the row

- High performance – also darkness

- High capacity

- Easy to operate, can be controlled by your smart phone, laptop or by its own display

- Power consumption is low; only about 1 hp pr row ; PTO of tractor

- Low weight 700kg (1500 lb)

- Can easily be adjusted to any row spacing 25cm – 75cm (9” – 30”)

- Operating speed: 2 – 8 km/h (1.2mph – 5mph)

- Automatic side shift; self centering

- Hydraulic operated

- Minimum maintenance

- Software installed for transplanted vegetables

- Can easily be updated with new software

- Each row has its own camera

Videos

Robovator working on Hemp in California

31 row machine working in lettuce, Germany

5 row machine working in chives, The Netherlands